Med internationellt ledande teknologi vill vi skapa tillväxt på hemmaplan.

Punktsvets och pinnsvets

Företaget Lösningar Applikationer Punktsvets och pinnsvets

Översikt

Punktsvetsning med Motomanrobotar

Not only large Automotive OEMs, but also European Tier1s, supplying car body subassembly plants, are very open to innovative products and lean approaches in spot welding.

There is a large field of spot welding applications in General Industry (outside of Automotive). YASKAWA Motoman is the right partner to realize spot welding solutions here.

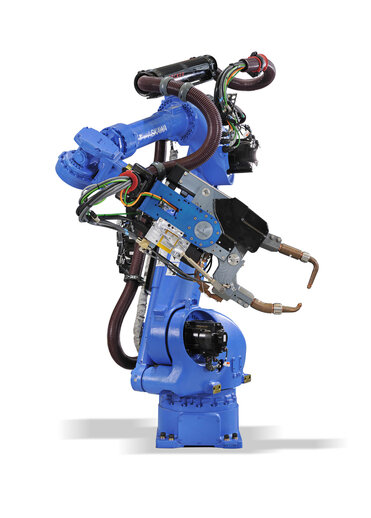

Punktsvetsrobotar

Punktsvetspaket med robot och kringutrustning

Nyckelfärdiga robotsystem för punktsvets

Kringutrustning

Our robot controllers interface with all common gun design and control methods, including:

- Pneumatic guns with additional pneumatic arm compensation

- Servo-Pneumatic guns compensated by the robot arms (only Automotive).

- Servo-Electric guns with separate gun controller (only Automotive).

- Servo-Electric guns controlled as a 7th axis, compensated by the robot arm (the most common solution both Automotive and General Industry)

By using mid-frequency inverters for DC welding, transformer sizes have been greatly reduced. We have also worked with gun manufacturers to utilize higher frequency inverter switching (1,800-2,000 Hz) to help reduce gun size and weight, resulting in a more efficient and smaller system. We are open to all Weld Timer suppliers, and support their signal exchange and weld parameter management softwares.

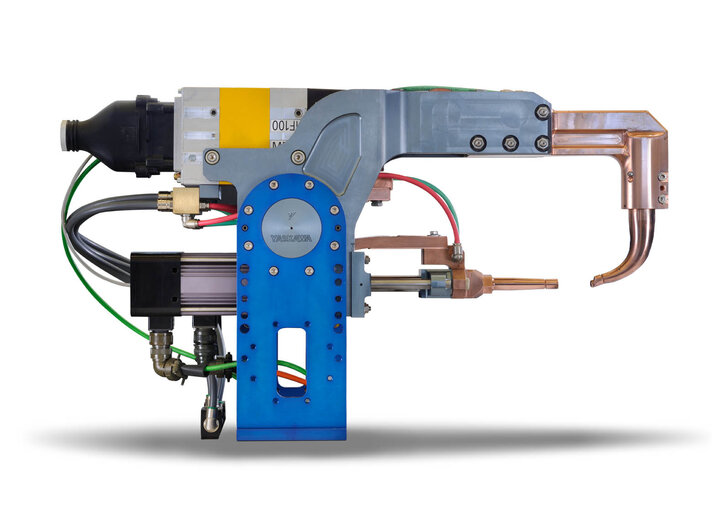

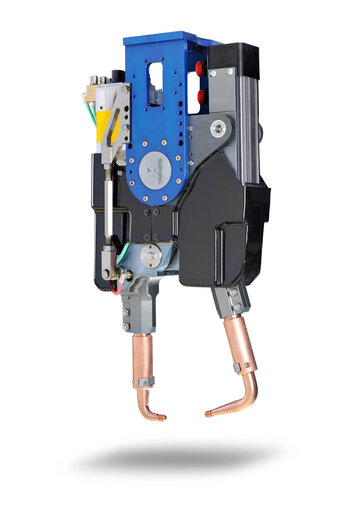

Punktsvetstänger av C- och X-typ

Servo Guns Software Options

A servo spot welding gun enables the robot to adjust electrode position based on motor torque feedback to provide the specified clamping force. Below are several benefits of servo guns:

- Minimizes electrode wear resulting in increased uptime

- Improves quality by providing consistent clamping force

- Improves Cycle time, as the gun can open/close in parallel to the robot's motion

- Eliminates “squeeze time” wait for an air-gun to close resulting in reduced cycle time

- Servo-controlled guns are more energy-efficient than pneumatic guns driven with compressed air, resulting in real cost savings

Our software provides easy calibration for X or C type guns and supports offsets for gun arm deflection and tip wear compensation. Stepped pressure files allow the gun pressure to be varied during the welding cycle or during a tip dress cycle.

The spot welding harness supports motor and encoder cables for Yaskawa Sigma-5 servo motors, which can be integrated with the gun manufacturers drives. Servo Drive Control kits are available for Yaskawa Motors, Obara lightweight motors, Tolomatic ServoWeld actuators and Exlar actuators.

Workpiece Positioners

We offer an extensive line of standard robotic positioners, all of them perfectly synchronized with the motion of robot and servo gun. One of the highlights is our RWV2 Turntable, with 1 or 2 robots sitting on top of a moving turntable - not beatable in terms of cycle time and installation space.

Tracks

With the TSL-1000, TSL-2000 and TSL-400 Series, Yaskawa offer a full portfolio of robot tracks, designed for Spot Welding and Handling Applications in Automotive Body Shop. All tracks are designing and manufactured in-house, ensuring highest expertise, quality, and attractive cost due to the short supply chain. All tracks are controlled by powerful Yaskawa Servo Motors and tuned to impressive motion speed while using high quality components.

Coordinated Motion and Multiple Robot Control

We were the first robot company to develop coordinated motion of multiple robots from one controller. Coordinated motion enables multiple robots to work within the same space without the risk of one robot interfering with another. This feature allows our robots to manipulate larger parts for multiple process robots or work closely together without collisions. Coordinated motion also extends to external servo axes in our positioners, simplifying complex operations.

Lap Spot Welding with Motoman Robots

Spot Welding is not always working with weld guns...

Pinnsvetsning

Ultrasonic Spot Welding Inspection with Motoman Robots

MotoSim offline-programmering och simulering

Offline Simulation Software Support and RCS Module

YASKAWA is supporting the vcomplete ecosystem of Offline-Simulation Tools, providing kinematic CAD robot models and RCS Modules.